|

|

|

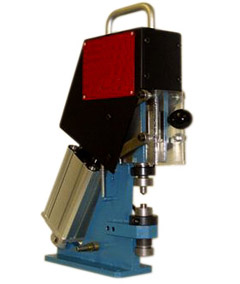

The Model 3P5 is a portable pneumatic press specifically designed for grommet applications. At only 16” tall and 3-1/2” wide, this powerful compact press is capable of punching a hole in a wide range of industrial fabrics and attaching a grommet and washer, all in a single cycle. The 3P5 is available in two versions; one for standard fabrics and a second for heavier fabrics and larger grommets. All of the setting tools are interchangeable, and are simply threaded in-place allowing for fast conversions. This machine is built on a sturdy welded frame and designed for safe operation, portability and ease of use.

|

|

|

Specifications:

Models 83, 83LT and 2R83

- Frame: Cast iron; dimensions overall: Height 24-1/2”; Length 23”; Width 12”

- Weight: Net 300 lbs, crated 350 lbs

- Stroke: 2-3/4” standard (Special strokes available 2” to 3-1/2”)

- Throat Depth: (center of Ram to Frame) 7-1/4”; Also available with throat depth to 15”

- Flywheel Speed: 200 RPM

- Motor: 1140 RPM, 1/4 to 1/2 HP as required

- Clutch: Sliding Dog Type and Non-Repeat Device

Models G83 and G2R83

- Weight: net, 330 lbs, crated 375 lbs

- Flywheel Speed: 140-160 RPM (Greater speeds available with brake)

|

|

We have a full line of the Model 83 Series of bench model eyelet and grommet attaching machines. These machines offer fast, reliable, efficient operation essential to meet the demands of your production. The Model 83 Series machines allow for all types of eyelets and grommets - round, oval, or square - to be automatically fed and set with equal simplicity and precision.

- Model 83 is used for eyelets with barrel dimensions ranging from .091” to .375” with a maximum flange diameter of .438”. Applications include:

- Single and multiple eyelet settings where materials are pre-punched or where an eyelet can cut its own hole

- Single eyelet settings where materials are pulled over spear point anvils.

- Model 83LT is used for single and multiple eyelet settings where materials are pre-punched. Model 83LT is used for eyelets with barrel dimensions ranging from .047” to .090”. An LT is the designation indicates the machine is equipped with the Limited Travel Spindle, an essential feature to maximize the life of the setting tools.

- Model 2R83 is used for single and multiple eyelet settings where materials are to be punched and eyelets set in one handling of the assembly. Model 2R83 is used for eyelets with a minimum barrel diameter of .125” and the maximum flange diameter of .625”.

- Model G83 is used for single grommet setting where materials are pre-punched. The washers, if used, are hand fed. This model is for grommets No. 00 to No. 5.

- Model G2R83 is used for a single grommet setting where perforating and setting is desirable with one handling of materials. Washers, if used, are hand fed. This model is for grommets No. 00 to No. 5.

The Model 83 Series machines can be used with interchangeable raceways for either single or multiple settings. In addition there are many other configurations of the Model 83 available for special applications.

|

|

|

Specifications:

- Grommet & Washer Feed: Automatic from rotating brush hoppers

- Motor: 1/2 HP, 115 VAC, 60 HZ, Single Phase

- Flywheel Speed: 140 RPM

- Throat Depth: 2”

- Compressed Air: Filtered 50-60 PSI, 0.2cfm

- Overall Dimensions:

2-1/2' W x 2-1/2' D x 5-1/2' H

- Crated Weight: 750 lbs

- Actuation: Electric Foot Switch

|

|

The Model 83GW automatically feeds and sets grommets and washers in a single revolution of the machine. 83GW tooling pierces most plastic or cloth materials while simultaneously feeding the washer with the eyelet or grommet. The result is a strong, durable quality setting with reduced operator fatigue, a safer operation, and a fast return on investment. The 83GW is especially suited for lighter materials as it pierces a hole versus punching a clean hole. With the pierce, the extra material folds back and provides a larger foundation to set the grommet and washer against.

Advantages:

- Increased Productivity: customers report increases in excess of 300% over conventional double revolution grommet machines

- Stronger Settings: material is not cut out, but is clinched between the grommet and washer

- Reduced Operator Fatigue: the operator simply positions the materials and cycles the machine

- Increased Safety: the operator does not have to place fingers in the setting area to load the washer

Safety:

- Completely guarded by wrap around A.B.S. plastic guarding

- Each machine comes equipped with one set of setting tools, rear gauges, left and right side gauges as required. The machine is mounted on a welded steel stand requiring a 30” square floor space.

|

|

|

Specifications:

- Frame: Cast iron; dimension: Height 24-1/2”; Length 23”; Width 12”

- Throat Depth: 7-1/4” (center of Ram to Frame)

- Stroke: 2-3/4”

- Flywheel Speed: 180 RPM

- Flywheel: 12-7/8” dia.

- Dual ³V”Belt Drive

- Clutch: Sliding Dog Type and Non-Repeat Device

- Motor: 1140 RPM, 1/2 HP, 120 VAC

- Electric: 115 VAC, 60HZ, 1 Phase

- Weight: Net 300 lbs, crated 350 lbs

|

|

Features:

- Flywheel & Belt Guards

- Ring Guard for point of operation protection

- Air Blow Off fittings for chip ejection

The Model G2R92 is a heavy duty machine designed to accommodate grommets form No. 1 to No. 5 inclusive. It is a double revolution machine that is used where punching a hole in the material and setting the grommet is desirable with one handling of materials. During the first revolution the hole in the material is cut and on the second revolution the grommet is fed and roll set. Washers, if used, are hand fed.

The Model G92 has the same features as the G2R92 except it is a single revolution machine that is used for grommet settings where materials are pre-punched. Washers, if used, are hand fed.

Both machines are equipped with 1/2 HP motors and can be used with interchangeable raceways and setting tools (within the limits of grommet sizes indicated). Ring guard or double palm button safety devices are also available for these machines.

Sample Settings:

Send us samples of your material in ready to be grommeted condition, along with some of your grommets and washers and we will be pleased to return sample settings for your approval.

|

|

|

Specifications:

- Grommet & Washer Feed: Automatic from rotating brush hoppers

- Motor: 1/2 HP, 115 VAC, 60 HZ, Single Phase

- Flywheel Speed: 140 RPM

- Throat Depth: 2-1/2”

- Compressed Air: Filtered 50-60 PSI, 0.2cfm

- Overall Dimensions: 3' W x 3' D

- Crated Weight: 850 lbs

- Actuation: Electric Foot Switch

|

|

The Model 92GW automatically feeds and sets grommets and washers in a single revolution of the machine. The 92GW is specifically designed to punch a hole in heavy duty industrial fabrics and feed and set a grommet and washer, all in a single revolution. The result is a strong, durable quality setting with greater productivity, all leading to a fast return on investment.

Advantages:

- Increased Productivity: customers report increases in excess of 300% over conventional double revolution grommet machines

- Advanced Cutting Technology: holes are punched in heavy duty Industrial fabrics including Kevlar and Nylon

- Compensator: to allow variance in material thickness of up to 0.125”

- Stripper Plate: to lift grommet and washer setting off of the pilot of the set die

- Grommet and Washer Sizes: No. 0 to No. 4 including telescopic and spur washers

- Reduced Operator Fatigue: the operator simply positions the materials and cycles the machine

- Increased Safety: the operator does not have to place fingers in the setting area to load the washer

Safety:

- Completely guarded by wrap around A.B.S. plastic guarding

- Each machine comes equipped with one set of setting tools, and rear side gauges as required. The machine is mounted on a welded steel stand requiring a 30” square floor space.

|

|

|

Specifications:

- Floor Space: 36” x 36”

- Work Height: 38” with optional B2424 Machine Stand

- Net Weight: 475 lbs net/600 lbs crated

- Frame: Cast iron; dimensions: Height 24-1/2”, Length 23”, Width 12”

- Throat Depth: 7-1/2”

- Electrical: 115 VAC, 60 HZ. Single Phase

- Pneumatic: Electro-Air foot trip that requires 50-60 PSI (.2 cfm) of compressed air

- Safety ring guard or dual palm buttons

|

|

The Model 98 is a semi-automatic grommet machine capable of handling heavy-duty industrial fabrics. The machine is designed to increase productivity, reduce costs, and safeguard machine operators. When the machine is actuated by the electro-air foot switch, a grommet is automatically fed from the raceway, the hole is punched and the grommet attached. All this occurs in one single cycle. A washer, if used, is hand loaded.

Features:

- Advanced cutting technology to punch a hole in heavy-duty industrial fabrics, including Nylon and Kevlar

- Flywheel powered to ensure consistent settings

- Compensator to allow variance in material thickness of up to 0.125”

- Available for grommet and washer sizes No. 00 to No. 4

Sample Settings: Send us samples of your material, in ready to be grommeted condition, along with your grommet and washer requirements and we will be pleased to return your sample settings for your approval with our formal quotation.

|

|

|

Specifications:

- Dimensions:

• Bench Space: 18”W x 22”D x 32”H

• On Stand: 24”W x 24”D x 64”H

- Weight / Crated:

• Bench: 375 / 400 lbs

• On Stand: 525 / 600 lbs

- Electrical: 115 VAC, 60 HZ, 1 Ph

- Motor: 1/2 HP, 1140 RPM

- Air: None

|

|

The Model 2KGW is a state-of-the-art, fully automatic, grommet and washer attaching machine. This machine is built around a newly designed frame that requires less space and is much lighter than previous generations of machines. The 2KGW is a fully automatic machine that feeds both the grommet and washer, punches the hole in the material and attaches the grommet and washer, all in a single cycle. This machine has been specifically engineered for light to medium duty applications.

Features:

- Flywheel powered and cam actuated to ensure consistent settings

- Advanced cutting technology to punch a hole in multi-layered materials

- Compensator to allow for a nominal variance in material thickness

- Stripper plate to lift grommet and washer setting off the pilot of the anvil

- Available for grommet & washer sizes No. 00 to No. 2 (including Telescopic, Tooth and Spur)

- Simplistic controls, operator and service friendly

Standard Equipment:

- Heavy Duty Machine Stand with 24” x 24” Table Top

- Laser Target Light

- Adjustable Spacing Gauge

Optional Equipment:

- Mobile Machine Stand with Casters (as pictured)

- Dual Palm Buttons

|

|

|

The Model SF2 is a fully automatic attaching machine tooled for industry snap fastener components. This machine is offered for customers looking for an affordable, reliable solution for snap fastener applications. The Model SF2 is a flywheel powered machine and features rotating hoppers to promote a consistent feed of the snap fastener components, a target light to for locating the snap position on the material, and a mechanical clutch with a non-repeat mechanism, to ensure long-term safe operation.

To find out how the Model SF2 can be put to work for you, please send us samples of your snap fasteners and material for application evaluation and we will be pleased to return the samples to you along with your formal quotation.

|

Specifications:

- Throat Depth: 2”

- Work Height: 33”

- Electrical: 115 VAC, 60 HZ, 1PH

- Motor: 1/4 HP

- Weight: 325 lbs

- Footprint: 18” Depth x 20” Wide

- Height: 51”

|

|

|

Applications include:

- Banners

- Signs

- Marine

- Flags

- Sports bags

- Canvas bags

- tonneau covers

- Tarpaulins

- Covers

- Automotive

- RVs

- Camper trailers

|

|

|

Both hands free so that the operator can grip the work properly.

The Laser light targets the center position for accurate and easy product placement.

Safety. The electric machine guard sensor stops the machine if fingers or other foreign objects interfere with the dies. There is a double-punching prevention mechanism with the foot pedal.

Comfort. The efficient design allows for ease of operation, while the stand height is adjustable for comfort and accommodates different users.

Portability. The 110volt plug makes it easy to move to any convenient location.

Ease of maintenance. The simple structure minimizes trouble, and when required it is not complicated to repair or replace parts.

The Automatic Compensation Unit allows fasteners to be fitted to any material with different thicknesses (within a tolerate range), without having to adjust the die height.

Changing products is quick and easy. With the simple exchange of tooling, the compensator will automatically adjust which allows for a variety of products to be set with this one piece of equipment.

|

|

|